Introduction

What is Eyewear OEM Manufacturing?

First, let us define OEM. OEM means Original Equipment Manufacturer. In the eyewear industry, you provide the designs and your brand. We handle the entire production process. We transform your creative vision into tangible high-quality products. This differs greatly from ODM manufacturing. ODM suppliers offer their own existing designs. OEM focuses on your unique brand identity. This guide is perfect for eyewear brands, designers, retailers, and startups.

Top 5 Benefits of Partnering with a Professional Eyewear OEM Manufacturer

Unmatched Expertise and Technology

Although eyewear may seem like a small accessory, its production relies on a comprehensive and sophisticated supply chain. This includes materials for frames, various components, and lenses. Professional eyewear OEM manufacturers utilize advanced technologies to ensure precision and quality. They employ CNC machining for mold manufacturing and 3D prototyping for sample development. Additionally, skilled artisans handcraft samples to meet specific design requirements.

Through years of expertise in eyewear manufacturing and ergonomic design, these manufacturers guarantee superior product quality. Their deep understanding of structural integrity and wearer comfort reflects in every product. This technical mastery ensures excellence in precision engineering and functional performance.

Cost Efficiency and Economies of Scale

Stringent Quality Control

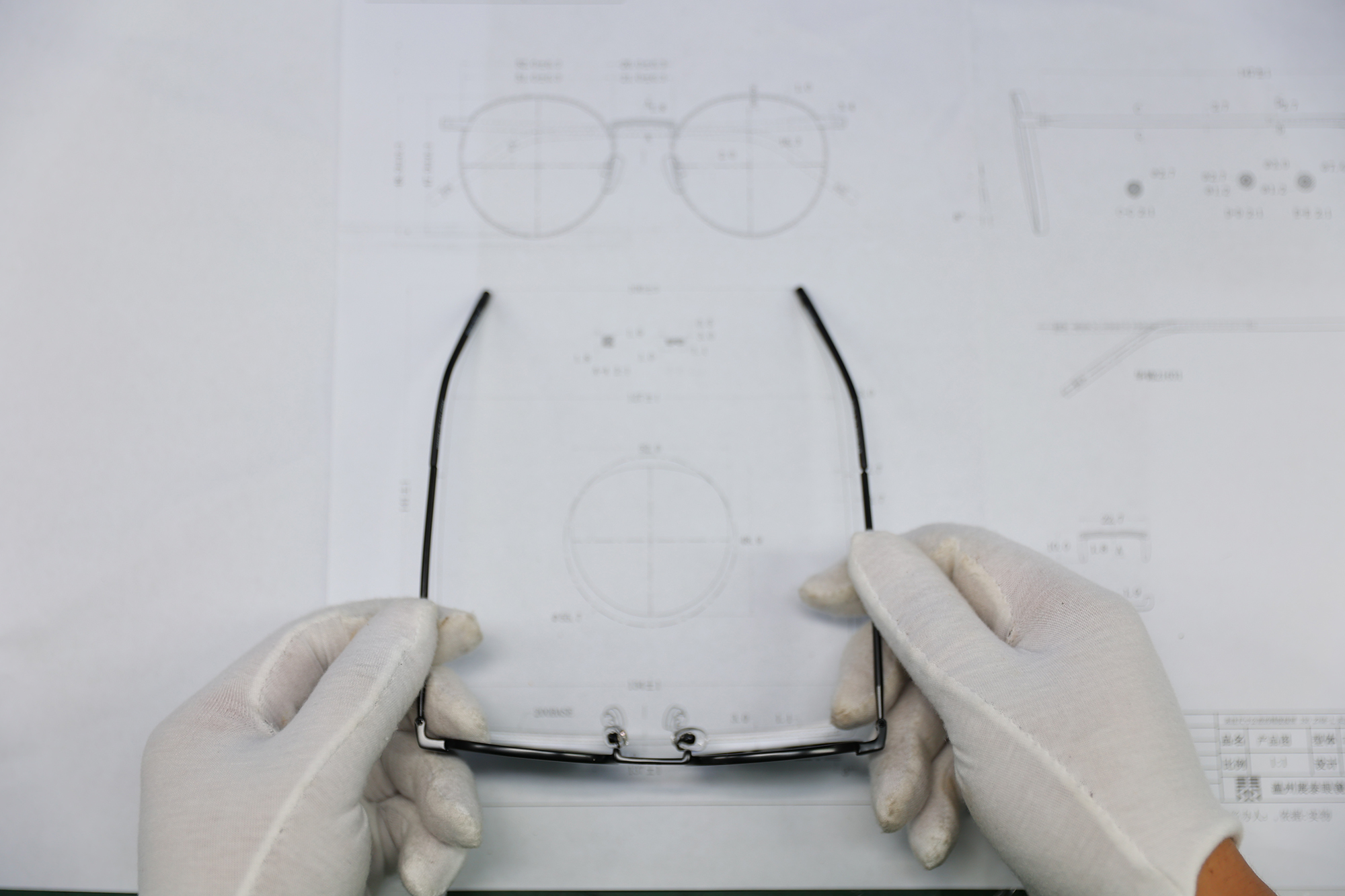

Quality is paramount throughout the entire production process. Leading eyewear OEM manufacturers maintain strict oversight at every stage. It begins with the careful selection of premium materials—including durable plastics, lightweight TR90, robust metals, and classic acetate. Each material is inspected to ensure it meets predefined standards before entering production.

During assembly, multiple rigorous quality checks are implemented. These inspections cover frame alignment, hinge functionality, surface finishing, and overall structural integrity. Additionally, specialized tests such as coating adhesion resistance and repeated opening-closing trials are often conducted. This meticulous approach guarantees that every pair of frames not only meets high aesthetic standards but also delivers lasting performance and comfort.

By enforcing such comprehensive quality control protocols, eyewear OEM manufacturers ensure consistency, reliability, and customer satisfaction in every order.

Focus on Your Core Business

Flexibility and Customization

Collaborating with an eyewear OEM manufacturer provides exceptional flexibility to support your brand’s unique needs. One major advantage is the support for low minimum order quantities (MOQ), enabling startups and established brands alike to produce smaller batches cost-effectively. Furthermore, you can customize nearly every aspect of your eyewear—from materials such as acetate, titanium, or TR90, to colors, hinge mechanisms, temple designs, surface finishes, and logo engraving techniques. This extensive customization capability makes an eyewear OEM manufacturer an ideal partner for custom sunglasses manufacturing and optical frame collections. Whether you aim to launch a new line or refresh an existing offering, this adaptability ensures your products align perfectly with market trends and consumer preferences.

The Eyewear OEM Process: From Concept to Delivery

Next, our engineering team develops your design. We create technical packages and 3D models. Then we produce physical samples for approval.

Afterward, you confirm material choices. We provide extensive material and color libraries.

Then, full-scale production begins. We maintain strict quality monitoring throughout. We often share inspection reports with you.

Finally, we conduct a 100% final quality check. We then handle packing and arrange reliable shipping to your door.

How to Choose the Right Eyewear OEM Manufacturer?

Selecting the best eyewear OEM manufacturer requires careful evaluation.

When choosing a manufacturing partner, it is essential to consider several key factors to ensure a successful collaboration.

Firstly, review the experience and portfolio of the potential eyewear OEM manufacturer. Examine their previous work for other brands to assess their capability and style.

Secondly, inquire about their Minimum Order Quantity (MOQ). A reliable eyewear OEM manufacturer often offers flexible order quantities that match your business needs.

Additionally, understand their quality control system. Ensure the eyewear OEM manufacturer implements rigorous inspection standards at every production stage.

Communication is another critical factor. Choose a supplier that responds promptly and has strong English skills to facilitate smooth interactions.

Finally, consider their range of services. The best eyewear OEM manufacturer typically provides comprehensive support, including design assistance and logistics management, to offer a truly one-stop solution.

Why Choose Zhantai Glasses?

Our business team is professional in many languages, including English, Japanese, French and Spanish, to communicate smoothly with our customers and provide satisfying services to them. With the service concept of “creating a new type of service-oriented enterprise”, our company has been expanding the international market, and our products are mainly exported to Europe, America, Southeast Asia and other countries in the world.

Ready to turn your eyewear ideas into reality? Our team is here to help you. Contact us today for a free consultation. Request a no-obligation quote for your project.

Email us directly at: [email protected]

We promise a prompt and helpful response.

FAQ Section

Standard lead time is about 45-60 days after sample confirmation.

What is your Minimum Order Quantity (MOQ)?

Our MOQ typically starting at 1200 pieces per model.

Do you provide samples?

Yes, we do. Sample cost and time depend on design complexity.

Which materials do you work with?

We specialize in Plastic, TR90, acetate and stainless steel.

Do you have international certifications?

Absolutely. We have CE, FDA, BSCI, ISO and other required certifications.