Finding a manufacturing partner may seem easy. However, finding a reliable sunglasses manufacturer is far more challenging. The right partner protects your brand reputation, delivers consistent quality, and supports long-term growth.

Whether you are an established brand like QUAY, a global retailer like MUJI, or a high-volume wholesaler, sourcing expectations have changed. Today, China sourcing goes beyond achieving the lowest unit cost. Instead, it focuses on supply chain resilience, technical innovation, and social compliance.

Therefore, brands must evaluate manufacturers more strategically. In this guide, we outline four critical pillars of eyewear procurement. Together, they help you navigate China’s manufacturing landscape and choose a partner with over 30 years of proven expertise.

The Challenges of Sourcing Sunglasses in a Global Market

The global eyewear market will reach new heights by 2030. However, for procurement managers, successful product launches remain highly complex. When sourcing from a sunglasses factory across the world, several challenges often arise.

First, value misalignment frequently occurs. Buyers approve premium pricing for advanced specifications, yet the finished product fails to meet expected quality standards. As a result, brands absorb high costs for average eyewear.

Second, communication gaps create costly mistakes. For example, unclear technical details such as bridge fit or hinge tension can produce thousands of unsellable units.

Third, compliance risks pose serious threats. Incomplete FDA or CE documentation often leads to customs delays, fines, or shipment seizures.

Finally, lead time volatility disrupts planning. Unstable production schedules can easily miss critical sales windows, including summer launches or Black Friday.

At Zhantai Glasses, we have refined our eyewear processes for over 30 years. Since 1990, our Wenzhou-based team has focused on eliminating these risks. We provide detailed Bills of Materials to ensure every dollar translates directly into frame quality. This guide condenses three decades of manufacturing expertise into a clear sourcing roadmap.

Step 1: Material Science as the Foundation of Quality Eyewear

A professional sunglasses manufacturer must master material science. In practice, the tactile feel of eyewear strongly influences a consumer’s perception of brand value. Therefore, brands should understand frame materials before issuing a purchase order.

TR90 as the Memory Plastic Gold Standard

In today’s competitive eyewear market, TR90 has become a preferred material for brands that demand both style and durability. Often called memory plastic, TR90 is a Swiss-developed thermoplastic that reshaped modern frame engineering. As a result, many sunglasses factories now rely on it for high-performance designs.

Why TR90 Is a Strategic Choice for Your Collection

1. TR90 delivers exceptional lightweight comfort. Its low density makes it about 20% lighter than acetate and far lighter than PC. Consequently, consumers experience reduced pressure on the nose bridge and ears, which supports long-term daily wear.

2. TR90 offers remarkable flexibility with shape recovery. Unlike traditional plastics, it bends under stress and consistently returns to its original form. Therefore, it significantly reduces breakage during shipping and accidental drops.

3.TR90 resists heat and chemicals effectively. It maintains structural stability under high temperatures, which matters for sunglasses left in hot cars. In addition, it resists skin oils and cosmetics, preserving surface finishes over time.

4. TR90 is hypoallergenic and skin friendly. It contains no BPA and does not irritate sensitive skin. For this reason, many brands treat it as the gold standard for active and lifestyle eyewear.

Strategic Brand Applications Across Market Segments

As an experienced sunglasses manufacturer, we see TR90 serving a focused, high-value segment. Specifically, it supports several distinct brand strategies.

Fashion-forward brands such as QUAY use TR90 to create bold silhouettes without excess weight. The material supports high-gloss finishes and saturated colors that define contemporary street-style eyewear.

Minimalist global retailers such as MUJI also favor TR90. Its durability and clean matte finishes align with a quality-first philosophy. As a result, brands justify mid-range pricing while maintaining strong perceived value.

In addition, performance and active brands rely heavily on TR90. Its impact resistance and strength make it suitable for high-velocity sports. At the same time, it avoids the added weight of metal frames.

The Zhantai Advantage

Although many sunglasses factories offer TR90, raw material quality varies widely. At Zhantai Glasses, we source premium-grade TR90 granules to ensure consistent shrinkage and uniform color. Moreover, our advanced injection molding process eliminates internal stress points. As a result, each frame achieves maximum durability and material lifespan.

Injection-Molded Plastics as the Scalability Powerhouse

If TR90 represents premium performance, then polycarbonate(PC) and cellulose propionate(CP) drive global scale. For a professional sunglasses manufacturer, these materials enable high output without sacrificing visual appeal. As a result, many large retailers depend on them for fast-moving collections.

First, polycarbonate(PC) delivers excellent impact resistance. Its natural shatterproof properties improve safety for high-volume lifestyle sunglasses. In addition, PC provides a solid hand feel that exceeds standard acrylic materials.

Next, PC and CP support cost-efficient mass production. These materials suit retailers such as Miniso and department store private labels. Therefore, brands can update styles quickly while maintaining competitive retail pricing.

The Zhantai Glasses’s Edge in Material Stability

However, material quality varies significantly across factories. Lower-tier sunglasses manufacturers often use recycled regrind materials. This practice leads to brittle frames and yellow discoloration in transparent colors.

At Zhantai Glasses, we avoid these risks entirely. We use only high-grade virgin granules with UV stabilizers. Consequently, clear frames remain transparent, and colors stay vibrant after long-term sun exposure.

Metal Frames and the Precision of Monel, Steel, and Titanium

While plastic frames dominate casual eyewear, metal frames deliver a refined and architectural aesthetic. As a result, they add premium contrast to any collection. As an experienced sunglasses manufacturer, we select alloys based on each brand’s market positioning and performance needs.

First, stainless steel serves as a durable all-round material. It is hypoallergenic and highly resistant to corrosion. Therefore, it performs well in coastal and humid environments where sweat and salt air affect lesser metals. In addition, its high tensile strength supports ultra-slim wire frames popular in Europe and the United States.

Next, Monel remains a classic industry choice. This nickel and copper alloy offers excellent malleability. Consequently, it enables intricate bridge structures and finely detailed temples.

Finally, titanium sets the luxury benchmark. It weighs about 40 percent less than steel while delivering exceptional strength. For this reason, many consider it a long-term or lifetime frame material.

Equally important, manufacturing quality defines metal frame performance. At our sun glasses factory, we use advanced electroplating and PVD coating processes. As a result, gold, silver, and gunmetal finishes resist chipping and peeling. This approach eliminates a common failure point in lower-grade production.

The Rise of Eco-friendly Materials

Sustainability is no longer a niche; it is a market requirement.

Bio-Acetate & Recycled Plastics: Look for a sunglasses factory that offers GRS (Global Recycled Standard) certified materials. This allows your brand to market “Green Eyewear” to the eco-conscious Gen Z demographic.

Step 2: Assessing Manufacturing Capabilities and R&D

Modern eyewear manufacturing combines traditional craftsmanship with advanced engineering. Therefore, when auditing a sunglasses factory, buyers must evaluate more than the assembly line alone.

In-House Design Capabilities and OEM or ODM Services

First, determine whether the factory only executes orders or actively provides solutions. This distinction directly affects development speed and product differentiation.

With OEM services, brands supply finalized 3D files, and the factory produces strictly to specification. In contrast, ODM services offer ready-to-brand designs that allow faster market entry. Brands can customize logos, colors, and finishes without starting from zero.

In addition, reliable partners provide rapid prototyping. At Zhantai, we convert 2D sketches into 3D printed samples within 48 to 72 hours. As a result, brands can evaluate fit and comfort before committing to costly steel molds.

Tooling and Mold Development Expertise

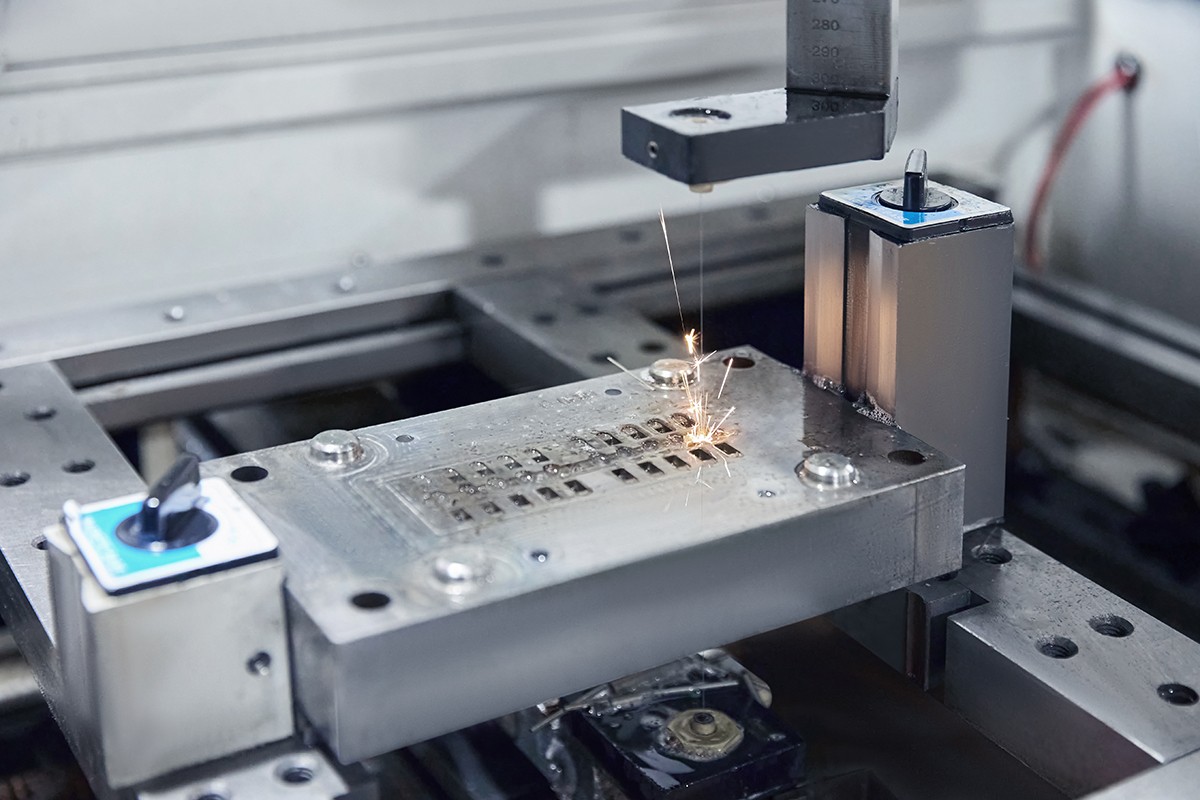

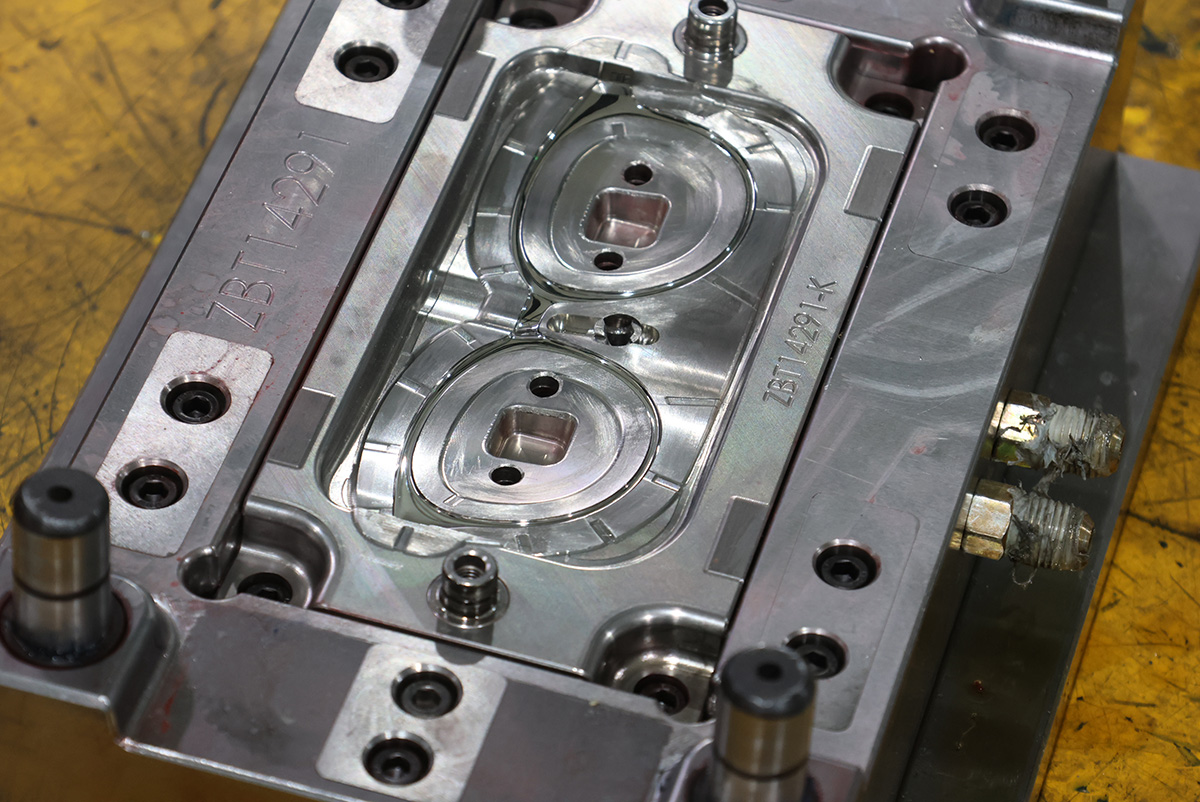

For plastic eyewear, mold quality defines product quality. Poor molds often cause excess plastic and visible seam lines, which reduce perceived value.

Therefore, we invest in high-precision CNC machining for mold development. This approach ensures each frame front and temple fits together accurately. Moreover, in-house tooling management shortens mold-to-sample timelines. Consequently, brands gain a clear advantage in fast-moving fashion cycles.

Production Capacity and Long-Term Scalability

Equally important, manufacturers must support sudden demand increases. Large retailers often require thousands of units per SKU each month.

For example, meeting large retail standards requires a monthly capacity of at least 500,000 to 1,000,000 pairs. In addition, automated injection molding and robotic painting systems ensure consistent color output at scale. Manual processes cannot achieve this level of consistency.

Zhantai Glasses Full-Service Retail Support Advantage

Over the years, Zhantai Glasses has served many supermarket and mass retail clients worldwide. Notably, many of these partners entered the eyewear category for the first time. Therefore, they required more than basic manufacturing support.

To meet this need, we provide complete eyewear solutions from concept to delivery. Our services include product design, material selection, mass production, and retail-ready packaging. Furthermore, we coordinate logistics and international shipping. As a result, our clients can launch eyewear programs confidently without prior industry experience.

Step 3: Verifying Compliance and Quality Standards

The Non-Negotiable Certifications

-

FDA Registration: Mandatory for the US market.

-

CE Mark (EN ISO 12312-1): Mandatory for the European Union.

-

ISO 9001: Proof of a functional Quality Management System.

-

BSCI/SEDEX: Social compliance audits that prove the factory treats its workers fairly—a must-have for brands like QUAY.

The 4-Stage QC Inspection Process

-

IQC (Incoming Quality Control): Testing raw plastic granules and lenses for UV400 protection before production starts.

-

IPQC (In-Process Quality Control): Checking frames immediately after they exit the injection mold for warping or air bubbles.

-

FQC (Final Quality Control): A 100% manual inspection of every pair for scratches, hinge tension, and alignment.

-

OQC (Outgoing Quality Control): A final statistical sampling (AQL 2.5/4.0) before the containers are sealed.

Step 4: Why Wenzhou Is the Premier Hub for Eyewear Production

When searching for a sunglasses factory, buyers usually compare Shenzhen and Wenzhou. Shenzhen specializes in high-end acetate eyewear. However, Wenzhou leads global production of plastic and metal injection sunglasses.

The Five-Mile Integrated Supply Chain

In Wenzhou, eyewear manufacturers produce every core component locally. These components include hinges, screws, nose pads, lenses, and custom packaging. As a result, suppliers coordinate faster and reduce supply chain friction.

First, localized production improves cost efficiency. Short transport distances lower logistics expenses. Therefore, brands benefit from a reduced cost of goods sold.

Second, the region supports rapid innovation cycles. When trends emerge on TikTok or Instagram, suppliers respond within days. Consequently, brands reach the market faster than competitors.

The Zhantai Glasses Legacy in Wenzhou

Zhantai Glasses represents more than a production facility. We operate as part of the Wenzhou eyewear ecosystem. Since 1990, we have grown from a small workshop into a large-scale manufacturer.

This long history reflects resilience and stability. Over time, we have adapted to every market shift. As a result, we offer partners the confidence of long-term cooperation for decades to come.

Conclusion: Moving From Sourcing to Partnership

Choosing a sunglasses manufacturer in China shapes your brand’s long-term direction. Therefore, this decision requires strategic evaluation. A low-cost factory may reduce unit prices today. However, it often damages brand reputation through returns and negative reviews.

For this reason, brands should focus on long-term value rather than short-term savings. A reliable manufacturing partner protects quality, consistency, and customer trust.

A Reliable Eyewear Partner Checklist

First, prioritize proven industry experience spanning over 30 years. Established manufacturers like Zhantai Glasses demonstrate long-term stability.

Second, confirm full eyewear OEM and ODM capabilities supported by rapid 3D prototyping. This ensures efficient development and faster decision making.

Third, verify in-house tooling and mold development capabilities. These resources directly improve quality control and lead time reliability.

Fourth, ensure certified compliance with FDA, CE, and BSCI standards. Proper documentation protects shipments and market access.

Finally, select a manufacturer located within the Wenzhou industrial cluster. This location maximizes supply chain efficiency and production speed.

Take the Next Step With Zhantai Glasses

Now is the time to elevate your eyewear collection. Whether you develop viral designs or source high-volume essentials, Zhantai Glasses delivers expertise and scale.

Therefore, contact our team today for a custom quote or a virtual tour of our Wenzhou facility.