3D printing is revolutionizing the eyewear industry by enabling customized, lightweight, and sustainable glasses.

-

What Are 3D Printed Eyewear? 3D-printed glasses are eyewear frames produced through additive manufacturing. This technology builds frames layer by layer from digital designs. It replaces traditional methods like injection molding. The process enables high customization, complex geometries, and rapid production.

-

Application Scenarios of 3D Printed Glasses in Current Eyewear Production

The Application of 3D Printed Glasses in Zhantai Glasses

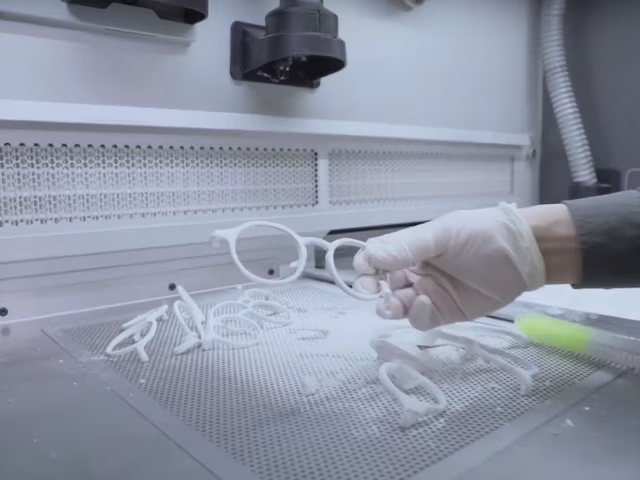

Zhantai Glasses uses 3D printing technology to produce sample glasses. We apply this method before formal injection molding. This rapid prototyping approach provides physical samples within 24-48 hours. It significantly shortens the traditional 1-2 week mold-making cycle.

Our clients evaluate designs through 3D printed eyeglasses samples. They visually assess overall proportions and structure. This process facilitates quick adjustments during early stages. Designers optimize based on physical prototypes.

Current 3D printed glasses presents some limitations. Precision constraints cause rough details on frames. Printed hinges often lack production-standard fineness. Chamfered edges appear less refined than final products.

Material differences affect quality significantly. Standard resins alter weight and flexibility. These materials create different textures from molded products. The variance leads to subpar wearing experiences.

Key contact areas require special attention. Nose pads need additional smoothing. Temple tips often need manual refinement. These areas may cause discomfort during extended wear.

Our team improves samples through manual polishing. We apply soft materials to critical contact points. These enhancements significantly improve wearability. We clearly explain the sample’s preliminary nature to clients. We emphasize the final product’s superior comfort and finish.

Advantages of 3D Printing Eyewear Production

1.Rapid Prototyping & Shorter Lead Times

Enables quick production of physical samples (within 24-48 hours), accelerating design validation and reducing the traditional 1-2 week mold-making wait time.

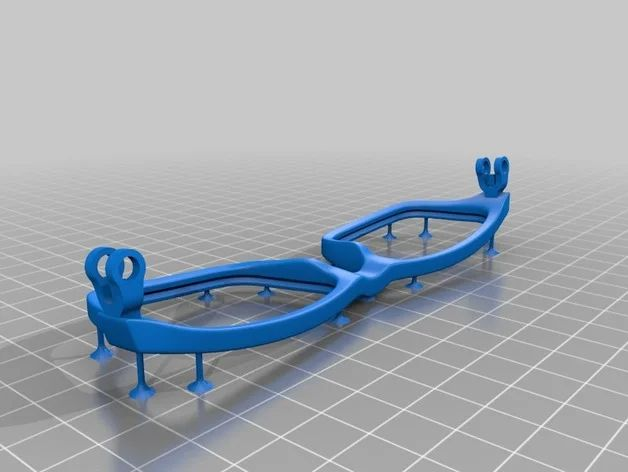

2.Design Freedom & Complex Geometries

Allows intricate, lightweight structures like lattice patterns or hollow frames that are impossible with traditional manufacturing.

Facilitates ergonomic optimization for better comfort and aesthetics.

3.Sustainability Benefits

Compatible with recycled plastics and bio-based materials.

Lower carbon footprint due to reduced logistics and waste.

Future Development of 3D Printed Eyewear

Technological advancements and shifting consumer demands will drive transformative growth in 3D printed eyewear. Several key trends are shaping this evolution.

-

Mass Customization & Consumer-Centric Production AI algorithms will automatically generate perfectly fitted frames by analyzing facial scans. Brands will provide web-based self-design tools for customers. Retailers will install in-store printing kiosks for same-day delivery.

-

Advanced Materials & Functional Innovation New polymers will replicate acetate aesthetics while improving durability. Manufacturers will adopt biodegradable materials like algae-based filaments. Companies will integrate electronics for AR/VR and health monitoring.

-

Hybrid Manufacturing for Premium Quality Eyewear will combine 3D printing with traditional craftsmanship. Artisans will hand-polish printed frames for premium finishes. Manufacturers will add metal alloy accents during production.

-

Scalability & Industrial Adoption Next-generation printers will reduce production time by over 50%. Brands will implement digital inventory systems. Companies will use on-demand printing to minimize waste.

-

Medical & Specialized Applications Developers will create hybrid prosthetic-optical solutions. Manufacturers will integrate corrective lenses directly into frames. These advances will serve post-surgery and vision-impaired users.

Conclusion

The industry will achieve hyper-personalization through tech integration. Sustainable production methods will become standard. Mainstream adoption will make perfect-fit eyewear universally accessible.